MKPro Engineering Pty Ltd

This is the Engineering Consulting arm of the group and is the delivery channel for our signature process engineering services.

Statement of Combined Experience

With extensive industry collaborations, you can benefit from our expertise and over 70 FTE years of combined experience in project engineering, front-end and detail engineering of plant and operations design using traditional, ConocoPhillips (‘CoP’) technology, and APCI LNG liquefaction processes, facility engineering, and project completion in the areas of gas processing, oil refining, and LNG technology; project engineering, front-end and detail engineering plant and operations for base metal and alluvial gold mineral process designs, Merrill Crowe process design, and detox plant designs; and designs for dangerous goods and handling of hazardous materials.

Our operational experience includes but not limited to process optimisation, offshore oil processing (FPSO), offshore gas processing, flow assurance and trunkline operations, onshore gas plant operations, LNG processing, gas sweetening, dehydration, fractionation and LPG extraction, condensate stabilization and domestic gas export, plant and process wide risk management including HAZOP, MHF, Process Hazard analysis, and Process Safety & root cause analysis, and management of top critical safety element.

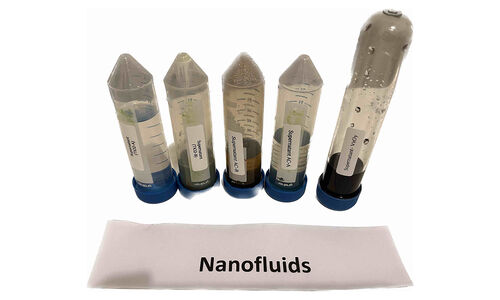

Deploying our proprietary technology and process, we have produced graphene (1.4 Å) and activated carbon (1.4 Å) nanoparticles from waste tyres, three variants of titanium oxide sub-nanoparticles (0.7Å), two variants of vanadium oxide sub-nanoparticles (0.9Å), and iron-cobalt nanoparticles (10nm) amongst others, while other nano and sub-nanoparticle complexes, —including with gold, silver, alumina, etc.— are in the pipeline.

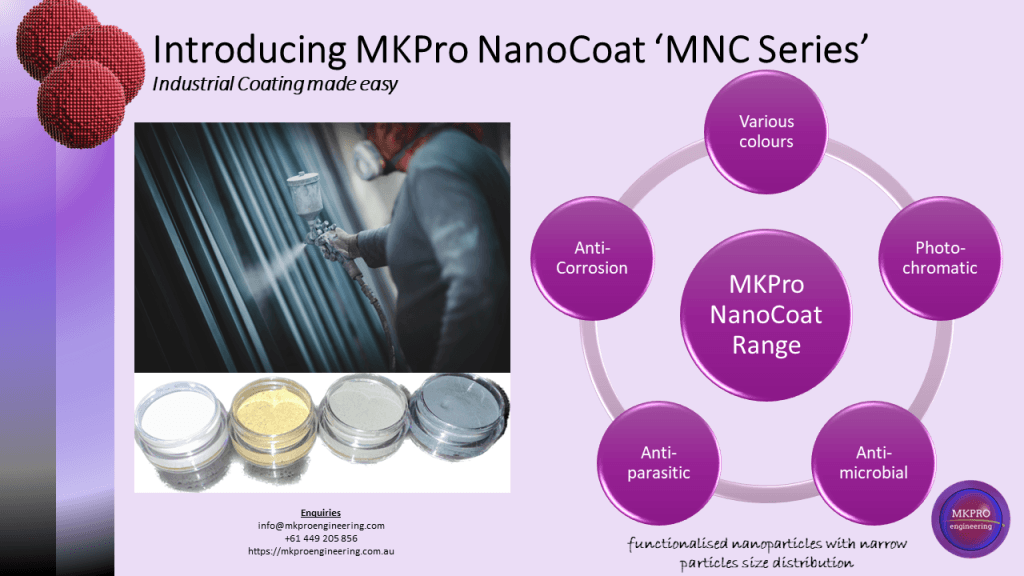

New Product

Follow some discussions on our collaborations and developments at:

Federation University – How nanotechnology is treading a new path for recycling or download the document here → How nanotechnology is treading a new path for recycling

The Courier- Dr Michael Akindeju draws closer to achieving nanotechnology goals or download the document here → Dr Michael Akindeju draws closer to achieving nanotechnology goals

The Courier- Dr Michael Akindeju hopes to make Ballarat a leader in nanoparticle production or download the document here → Dr Michael Akindeju hopes to make Ballarat a leader in nanoparticle production

We also have experience with business process optimisation including process discovery, improvement, and re-engineering.

Our range of Chemical Engineering products and services include:

- Research & Development

- Chemical Process Engineering Consultancy

- Nanoparticle Systems & Advance Manufacturing

- Business Process Engineering Consultancy

Where feasible and required, we deploy our patented Integrated Circuit Network Reactor design approach to enhance process yield within fixed volumes to optimise resources and reduce operational complexity for our clients.

Research and Development

We focus our R&D efforts on generating work efficiencies, buttressing sustainable systemic performances, improving quality of life, and enhancing public and social health outcomes. For some of these, please visit our research outputs.

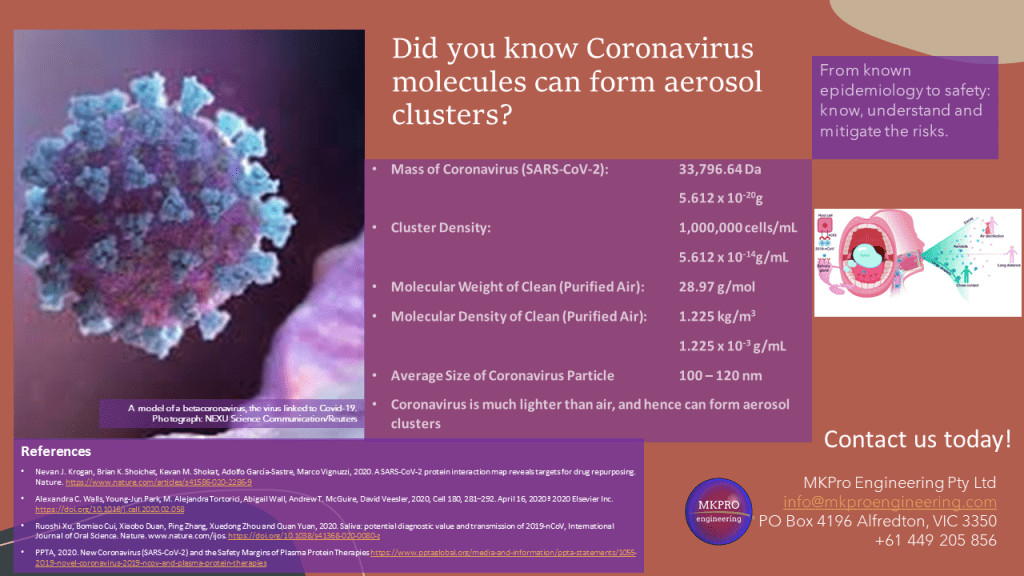

MKPro Responding to Coronavirus outbreak

We were amongst the first that modeled and advised Public Health agencies on aerosol mode of corona virus transmission.

What Our Clients Say

Dr Ebenezer Sholarin

Founder & CEO, Solarben Group. Entrepreneur, Educator, Train

I have worked with Michael Akindeju on professional and personal level. As a Chemical process engineer, I found him to be a consummate professional with excellent people management skills. His superior emotional intelligence quotient places him on a higher performance level far above his peers. He has my highest recommendations.

Michael Trenorden

Engineering Manager at Gekko Systems

Michael Akindeju has very strong understandings of all aspects of process engineering. His back ground and skills also allows him to research and apply new skills quickly and with fantastic results for the client. No problem is too hard for Michael and he seems to enjoy the challenge of taking on problems other people try to avoid.

Vanessa McCallum

Mechanical Engineer / Project Manager at Build Run Repair

I have had the pleasure of working with Michael Akindeju for the past 6 months in the engineering team at Gekko Systems. Michael has great attention to detail and can work well under tight time constraints. He is fully aligned with safe working practices and understands the steps required to provide a safe and robust engineering design. On a personal note, Michael has a good sense of humour and enjoys working in a team environment.

Chaudry Ahsan Amin

Key Account Manager at AAM

Michael supervised my thesis for my B. Engg Chemical (Hons) degree. I found him an excellent mentor who helped my team and I develop process engineering and academic research skills, and his mentoring towards me has extended past academics to the professional arena. He is knowledgeable in his field, methodical in his approach to projects, systematic in problem solving and has good interpersonal skills.

Ashwin Amarnath

Energy Professional (Masters of Renewable & Future Energy Ca

Michael was my tutor at university in my first year of study. During this time, he was influential in helping myself and students understand the wider applications of engineering solutions and to think broadly. He also served as a mentor, extending and enriching my experiences within the field of engineering. I am pleased to recommend a person like Michael who is honest and conducts himself with integrity at all times for any opportunities in the future knowing he will be a valuable asset.

Damon Buchanan

Technical Process Superintendent at Kirkland

I can highly recommend Michael in the mineral processing field. Michael conducted a throughput increase review for my department in 2017. The report was professional, as per scope, on time and had very interesting solutions that were well thought out and made use of the limited resources available at that time

Ken Donaldson

Operations Superintendent – Copper and By Products at Nyrsta

Michael Akindeju provided Process Engineering support to the Services Group at Gekko Systems. I found him very capable, with advanced theoretical knowledge that underpinned a friendly and enthusiastic approach to our requirements. It was a pleasure working with Michael.

Louise Franklin

Engineering Manager – Manufacturing at MaxiTRANS

Michael Akindeju worked as a key contributor to small, medium and large projects during his time at Gekko Systems Pty Ltd. A significant amount of his time was spent on a large project which required contributions during the design, manufacturing, installation and commissioning phases. This project was successfully handed over the client and is currently in its first couple of months of operation. Michael was always prompt, accurate and appreciated the importance, and the complex nature of project inputs in the mineral processing industry. He was a quiet, well mannered, valued member of the team.

Tim Hughes

Process Engineering Manager at Gekko Systems Pty Ltd

Michael Akindeju worked with me on the Hera base metals project from the commencement of detailed design to successful commissioning. As this period was less than 16 months, we had to work very quickly and efficiently and Michael was outstanding in this regard. His dedication to getting the job done was a critical part of this successful project and to all the work we did together at Gekko systems and I have no hesitation in recommending him.

Rawand Kader

I studied and worked with Michael Akindeju. It is rare to find the quality engineers who are good not only technically but also in economics, project costing and management, banking and finance, reporting and who are good team members and always willing to help and share knowledge. You will find all of that in Michael. Michael pays attention to details and always endeavours to deliver excellence and his tasks.